PRODUCTS

High Performance Trays

(TCMV, TDV)

Weakness of

Conventional Trays

- Poor Liquid Flow Distribution

Uneven bubbling activity / Stagnant liquid pools - High Liquid Hydraulic Gradient

Low bubbling activity at tray inlet / Poor vapor distribution - Non-optimized Downcomer Design

Oversized downcomer / Premature downcomer flooding

Conventional Trays

Stagnant Liquid pool

High Performance Trays

Liquid Plug Flow

Background

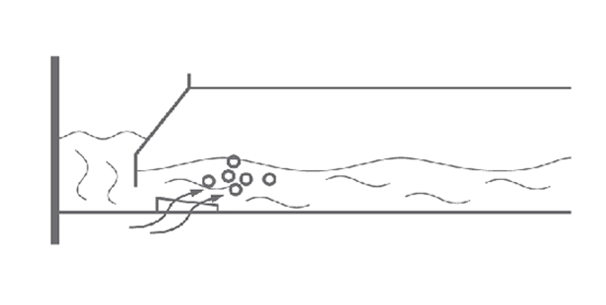

Conventional trays typically form stagnant liquid pools on both sides of the

tray decks (left). To eliminate this inherent stagnant liquid pool, it is necessary

to improve liquid flow distribution across the tray floor. As shown in the

Figure (right), uniform plug-flow liquid distribution eliminates liquid back-mixing

and the formation of stagnant liquid pools. As a result, plug flow distribution

improves tray efficiency and also minimizes the tray tendency to foul. The

High Performance Tray technology consists of various design know-how

that help, not only improve column throughout and efficiency,

but also extend the column run-time.

High Performance

Tray Design

Mini Valve & Micro Dispersion Valve

Mini valves which are available for round and rectangular type

valves, with the design feature of directional flow promotion

devices help eliminate stagnant liquid pools and promote uniform

liquid plug flow and froth densities across the entire bubbling area.

Directional promotion devices eliminate fouling material settling

on the tray deck and thus serve to extend the column run time.

Inlet Bubble Promotors

The High Performance Tray is designed with unique inlet bubble

promotors, shown in the right side figures, to allow for froth in

initiation near the inlet area of the active panels. The froth

initiation helps minimize/eliminate the liquid gradient on the tray

and promotes uniform froth distribution across the entire tray

active area, which results in higher tray capacity and operating

flexibility.

Apply Downcomer Optimization

Optimize bubbling area

Downcomer area distribution

Use vapor tunnel and relief downcomer concepts

Advantages of TPT’s High Performance Trays

(TCMV(F), TRMVF, TDV)

When compared with typical conventional

valve/sieve trays, High Performance Trays offer:

Higher capacity – typically 20 – 40%

Higher tray efficiency – typically 5 – 15%

Lower pressure drops – typically 15 – 20%

Higher turn down flexibility

Longer column run-time.

| Features | Advantages |

| Greater effective active area | Higher capacity |

| Special contact device | Higher capacity & efficiency |

| Longer effective flow path | Higher efficiency |

| Directional flow | Improved liquid distribution |

| Bubble promotor | Higher capacity & efficiency due to froth initiation |

De-entrainment Device

The objective of high performance tray with de-entraining devices is to

effectively eliminate entrainment in such operation cases. Another

benefit is additional wetted solid surface area for enhanced vapor and

liquid contact.The de-entraining device, comprised of a plurality of

baffles, is situated in the disengagement zone below the tray. The

baffles act as spray deflectors by intercepting entrained spray.

Liquid then falls as droplets toward the active area.

When operating under the spray regime, the high performance trays

with de-entraining device can result in an increase of approximately

10% – 20% additional hydraulic capacity over trays without such a device.

It have been successfully applied in commercial distillation columns and

are proven effective, with technical advantages, under variable conditions.

ENTRAINMENT

- A.

- 1st Floor Hanaro Building, 25, Insadong 5-gil,

Jongno-gu, Seoul, 03162, Korea (Head Office)

- T.

- +82) 2-6356-2550 (Head Office)

- T.

- +82) 52-237-2720 (Shop)

- E.

- tpt@tptpacific.com