SERVICES

Divided Wall Column (DWC)

DWC Technology

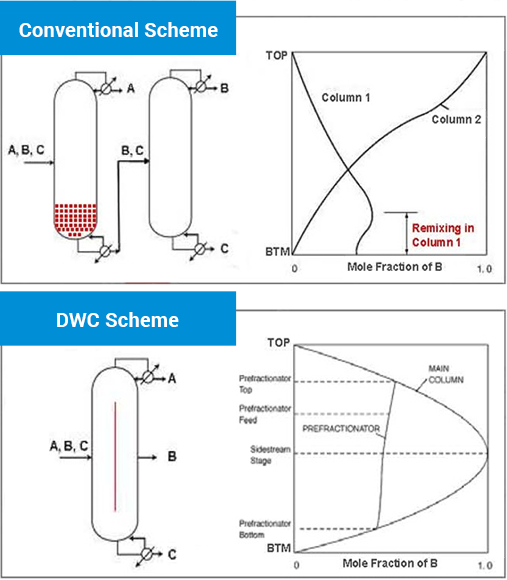

Conventional scheme for the separation of

three components

In the first column, the intermediate volatility component B reaches a

maximum somewhere in that tower, but necessarily must be lower.

This represents a thermodynamic loss (remixing) that is unavoidable in

the sequential distillation scheme.

Alternative Arrangement

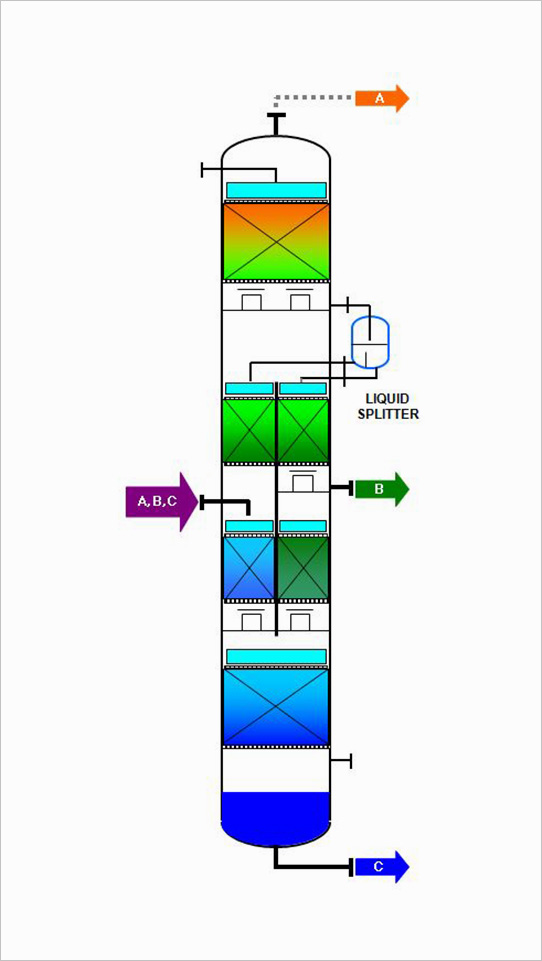

The two towers are thermally integrated to one tower. The first portion of

the tower is pre-fractionator, and the second portion of the tower is main

tower. The feed enters into the side of the pre-fractionator. The entire A

and some fraction of B will go over the wall to the upper section of the

main tower. The remaining fraction of B and the entire amount of C will

go under the wall to the lower section of the main tower. The top, bottom

and side product in the main tower will be A, B and C, respectively.

This arrangement can remove remixing.

high efficient distillation technology

TPT achieved the successful operation of DWC Technology in many separation columns in petrochemical plant.

Benefits of TPT’s DWC

Energy Saving (20~30%)

Reduce the Investment Cost

What TPT do in mass transfer application for DWC ?

DWC Modeling & Simulation

Optimum DWC Design

High Performance DWC Internal Design & Supply

Column Modification & Internal Installation

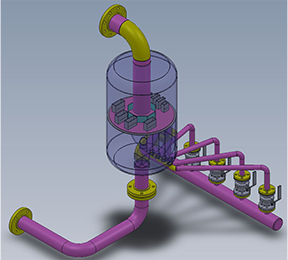

Liquid Splitter Design & Supply

Typical application of DWC technology

Octanol Separation Plant

Bio-Disel Plant

VAM Plant

NPG Separation Plant

Aromatic Plant

Solvent Recovery Plant

Other Chemical Separation Plant

Non-moving type

Various split range

- A.

- 1st Floor Hanaro Building, 25, Insadong 5-gil,

Jongno-gu, Seoul, 03162, Korea (Head Office)

- T.

- +82) 2-6356-2550 (Head Office)

- T.

- +82) 52-237-2720 (Shop)

- E.

- tpt@tptpacific.com