SERVICES

Column Scanning

Look inside your column while it’s operating

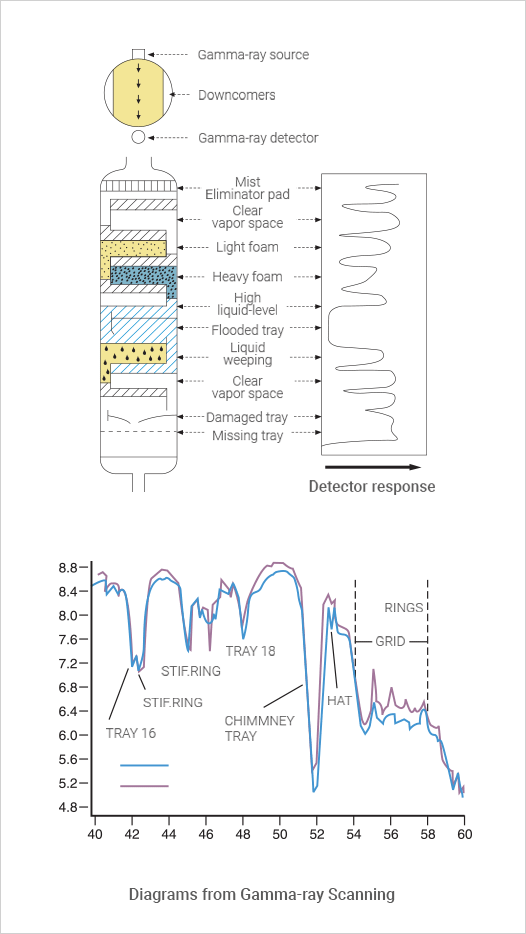

Gamma-ray scan testing is a non-invasive technique that can

be used to look inside towers and vessels to examine the

abnormal operation and to obtain the data for revamp. Using a

collimated beam of Gamma-rays from an enclosed millicurie

radio-isotope source, one can determine a density profile and

interpret the scan to produce a detailed picture of what is

(or isn ’t) inside and what is (or isn’ t) happening.

Gamma-ray scan can identify these

conditions and determine their causes

Displaced or damaged trays and packings

Flooded trays and packings

Foaming on trays or in reboilers, condensers and accumulators

Weeping or dumping trays

Flooded downcomers

Maldistribution of vapor and liquid in packings

Fouling, plugging and coking

Unequal liquid levels on trays and in parting boxes,

troughs and collectors

Almost all column operating problems

fall into one of these classes:

Operation is poor right from start-up

Performance deteriorates gradually over time

An upset degrades performance

- A.

- 1st Floor Hanaro Building, 25, Insadong 5-gil,

Jongno-gu, Seoul, 03162, Korea (Head Office)

- T.

- +82) 2-6356-2550 (Head Office)

- T.

- +82) 52-237-2720 (Shop)

- E.

- tpt@tptpacific.com