APPLICATIONS

최근 글

글 목록

카테고리

그 밖의 기능

APPLICATONS FOR MASS

TRANSFER PROCESS

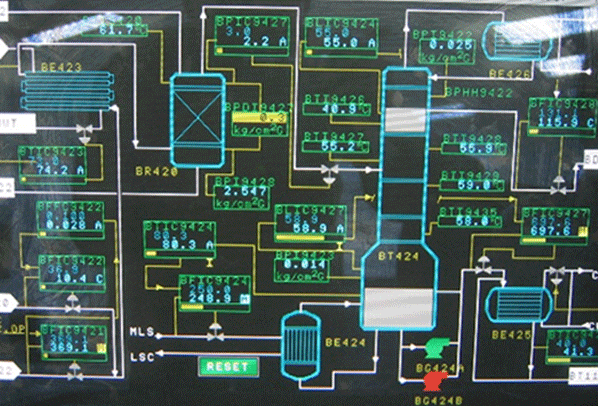

TPT has optimum solution for the mass transfer operations based

on the ample experiences. TPT has developed beyond the state of

the art breakthrough separation equipment and systems for mass

transfer applications.TPT has performed the process simulation for

the specified process and served best solution to improve the

process and increase the plant capacity such as following process.

– Aromatic Unit ( Pre-distillation, BTX Extraction, Fractionation.. )

– PTA Process ( Dehydration, MA Hydrolysis.. )

– 1,3 Butadiene Process ( DMF, NMP, ACN )

– Linear Alkyl Benzene

– Oxo-alcohol Plant

– MMA

– TDI / MDI

– Acid Gas Removal ( MDEA, DIPPA… )

Aromatic Unit ( BTX Extraction )

TPT did process simulation using TPT’s own thermodynamic

model for actual operating plant. And we offered best

solutions for client’s need, capacity increase, purity

improvement and energy saving. TPT supplied high

performance extraction tray for extractor, high performance

tray/ packing for stripper and recovery column.

PTA Process ( Dehydration & MA Hydrolysis )

TPT did process simulation using TPT’s own thermodynamic

model for azeotropic distillation using NBA, IBA as solvent and

simple distillation column. And we offered best solutions for

client’s need, capacity increase, purity improvement and energy

saving. TPT applied high performance extraction process for

dehydration system to reduce the energy and investment cost.

TPT also serve the basic engineering and supply the main

equipment of MA ( Methyl Acetate ) hydrolysis plant. TPT’s MA

Hydrolysis process produces acetic acid, methanol and water

mixture with high yield and efficiency.

process

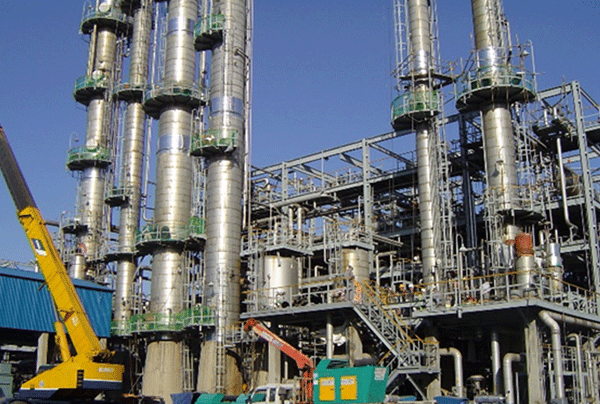

1,3 Butadiene Production

TPT did process simulation using TPT’s own thermodynamic

model for extractive distillation using DMF, NMP & ACN as

solvent. And we offered best solutions for client’s need, capacity

increase, anti-fouling solution for 1st EDC, 2nd EDC and

fractionation column.

Linear Alkyl Benzene

TPT did process simulation using TPT’s own thermodynamic model

and offered best solutions for client’s need, capacity increase.

Oxo-alcohol Plant

TPT did process simulation using TPT’s own thermodynamic model and offered

best solutions for client’s need, capacity increase, energy saving of isomer column.

MMA / TDI / MDI Plant

TPT did process simulation using TPT’s own thermodynamic model and offered best

solutions for client’s need, capacity increase.

Acid Gas Removal

Acid gas ( H2S, CO2..) shall be removed from light hydrocarbon product.

TPT did process simulation using TPT’s own thermodynamic model and offered best

solutions for client’s need, capacity increase of absorber and regeneration column.

- A.

- 1st Floor Hanaro Building, 25, Insadong 5-gil,

Jongno-gu, Seoul, 03162, Korea (Head Office)

- T.

- +82) 2-6356-2550 (Head Office)

- T.

- +82) 52-237-2720 (Shop)

- E.

- tpt@tptpacific.com

최근 댓글